Go back

Decarbonising Maritime Transport

Ayesa delivers two new LNG Bunkering stations for Bilbao and Santander ports

- Client: Repsol

- Date: 2021 - 2022

- Location: Bilbao, Spain

- Sector: Industry, Oil and Gas

- Subsector: GNL

- Investment: 20 M€

Go back

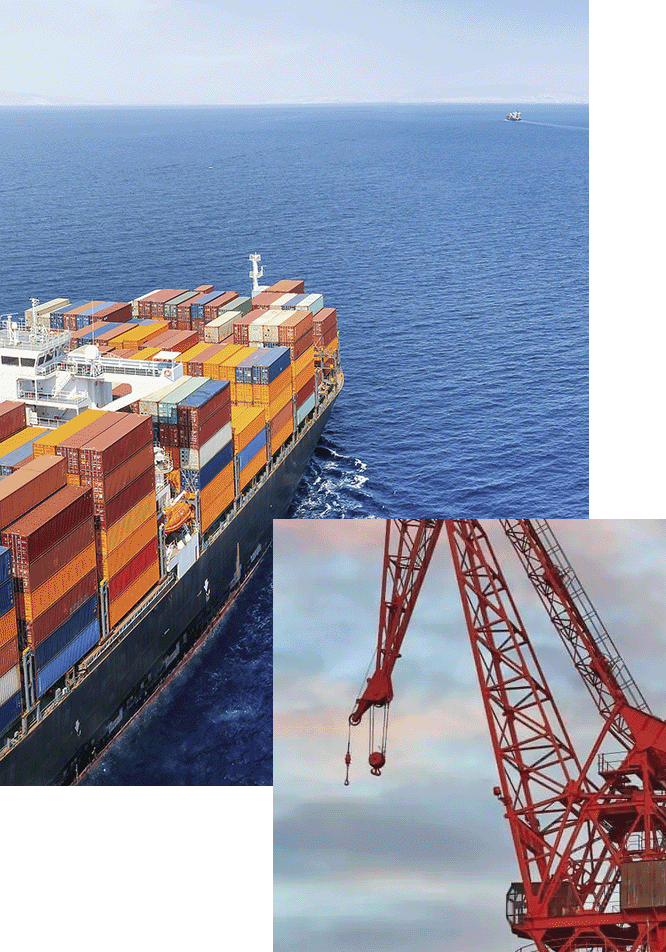

Decarbonising Maritime Transport

The maritime shipping sector heavily depends on fossil fuels, accounting for 3% of the world’s greenhouse gas emissions. Despite this, it is considered the backbone of the global economy as it contributes to over 90% of the worldwide trade volume. Many ports are now adapting their landside infrastructure to accommodate alternative fuels such as liquefied natural gas (LNG).

Currently, 38% of European ports offer LNG refuelling services, while an additional 24% have plans to invest in this technology. By utilizing alternative energy sources such as LNG, ports can significantly reduce their emissions of sulfur oxides (SOx), particulate matter (PM), CO2, and nitrogen oxides (NOx), which helps improve air quality. Furthermore, LNG terminals can also receive and store green hydrogen, which will be important in the energy transition.

Our client Repsol set the objective to move towards sustainable shipping and net-zero emissions by 2050. The construction of new LNG terminals in the ports of Bilbao and Santander, designed to provide a “port-to-ship” service, is a crucial step in this process. Repsol is a Spanish multinational energy company engaged in all aspects of the oil and gas industry and has a significant presence in renewable energy with operations in over 40 countries worldwide.

Repsol appointed Ayesa to design, procure and deliver this specialist infrastructure. Our role was to create a flexible design that would cater to various vessels and deliver the terminals within a strict turnaround time of 2 years. Both terminals have received co-financing from the European Commission through the CEF – Connecting Europe Facilities Programme.

Ayesa has successfully executed the detailed engineering and managed the design procurement process for these two LNG terminals based in the ports of Bilbao and Santander. This remarkable project was multi-disciplinary in nature, involving a variety of disciplines, including process, mechanical equipment, pipes, civil, electrical, and instrumentation design.

The newly constructed terminals boast state-of-the-art features such as LNG tanker unloading systems, storage, ship delivery and NG vapour return lines, safety and control systems, encapsulated flares, and other landside facilities.

These facilities have been designed to meet the highest safety and operational standards, ensuring the effective refuelling of LNG to vessels and ships. The impressive cryogenic tank in the terminals can store up to 1,000 cubic meters of LNG at a temperature of -160ºC, ensuring that the natural gas remains liquid until deployed.

Bilbao Port commenced construction in 2021 with an investment of over ten million euros. The port was fully operational as scheduled by Mid 2022.

Ayesa has a proven track record of designing LNG facilities and has successfully completed numerous bunkering projects worldwide. Moreover, they have undertaken over 20 engineering and procurement management actions for Repsol, accomplishing their objectives in fast-track mode in just two years with over 30,000 man-hours of engineering and management.

By adopting an innovative approach, Ayesa has added exceptional value to the project by delivering Spain’s first-ever LNG storage terminals. These terminals can store and supply LNG near the loading points of ships, catering to future bunkering needs and adding more value to the project.

The success achieved in record time sets an example for the industry, emphasizing their expertise in the field.

Ayesa’s services included an extensive range of engineering and procurement management, from unloading systems to general facilities and urbanization, including LNG storage systems, vapour return lines, safety and overpressure systems, flare systems, LNG loading systems, DCS, ESD, F&G systems, and ICS systems.

Overall, Ayesa’s exceptional expertise and experience in the LNG industry have made them a game-changer, constantly pushing boundaries and setting new benchmarks.

2000m3

cryogenic storage

600m3/hour

continuous filling capacity

Our goal is to provide you with the best services for your needs