Challenge

Since 2014, the Environmental Protection Agency (EPA) has identified multiple locations across Ireland where raw sewage continues to discharge untreated into rivers and seas—posing serious environmental risks. In response, Uisce Éireann (Irish Water) has made significant infrastructure investments to tackle these long-standing wastewater challenges. One such investment is the Arklow Wastewater Treatment Plant, which serves a rapidly growing commuter town just 90 minutes south of Dublin.

The project follows decades of delays and setbacks. First proposed in 1988, it encountered numerous challenges—including a controversial site change in 1993, initial planning permission granted in 1994 that stalled for more than 30 years, renewed approval in 2005, and lapsed permissions in 2015. Real progress only began after Uisce Éireann took over responsibility in 2016. Planning permission was granted by An Bord Pleanála in 2019, with the project going to tender in 2021 and construction starting the same year at the North Dock site. Remarkably, the facility was completed six months ahead of schedule in November 2024 and commissioned in January 2025.

Delivered under a Design-Build-Operate contract with a four-year delivery timeline, the project team included Wicklow County Council, Ayesa, Ward & Burke Construction Limited, and Clancy Moore Architects. Already recognised with the prestigious Downes Medal—an exceptional honour for utility infrastructure—the facility sets a new benchmark in sustainable civic design.

The plant will prevent untreated wastewater from entering the Avoca River and the Irish Sea, bringing Arklow into compliance with EU environmental regulations. It has an initial treatment capacity of 24,000 population equivalent (PE), scalable to 36,000 through modular upgrades. Beyond regulatory compliance, the facility supports a growing population, strengthens flood resilience, and represents a major investment in the long-term health and wellbeing of the local community.

Our work

Uisce Éireann appointed Ayesa to provide consultancy services across all phases of this critical wastewater treatment plant (WWTP) project. Our role is based on our extensive experience in delivering water infrastructure in the area, having previously been appointed as engineers for the Arklow Water Supply Scheme and the Arklow Flood Relief Scheme (FRS). This deep understanding of the full water cycle within the catchment allowed us to adopt a strategic and holistic approach, particularly in managing the shared interfaces between wastewater, flooding, and climate resilience.

Phases 1 & 2: Design of Preferred Routes

Ayesa, working in collaboration with Arup, developed the preferred design for the new interceptor sewers that would transport wastewater to the plant and the outfall pipe that would safely discharge treated effluent into the Irish Sea. This phase was highly complex, requiring detailed hydraulic modelling, environmental impact assessments, and strategic stakeholder engagement.

Key tasks included:

- Hydraulic and environmental analysis using InfoWorks ICM, an advanced integrated catchment modelling tool, to determine optimal sewer alignments.

- Comprehensive surveys and assessments, including flood risk assessments, site investigation works, bathymetric surveys, structural surveys, flow & load, rainfall monitoring, topographical mapping, marine studies, noise assessments, and ecological impact evaluations.

- Stakeholder coordination, assisting Uisce Éireann (Irish Water) with Compulsory Purchase Orders (CPOs), Utility diversions, landowner agreements, and presenting at the Environmental Impact Statement oral hearing.

One of the most challenging aspects of the design was selecting the best route for the interceptor sewers. The topography of Arklow and the termination of all outfalls at the river provided only two viable locations for these sewers—at the North and South Quays. This required the construction of a tunnel pipeline linking both sides, allowing wastewater to be transferred to the new plant.

Gates 3 & 4: Construction & Delivery

With planning, land acquisition, and environmental licenses secured, Uisce Éireann (Irish Water) appointed Ward & Burke as the contractor for the scheme. Following a competitive tender, Ayesa was selected as Employer’s Representative, providing contract administration and overseeing project delivery.

Key construction milestones included:

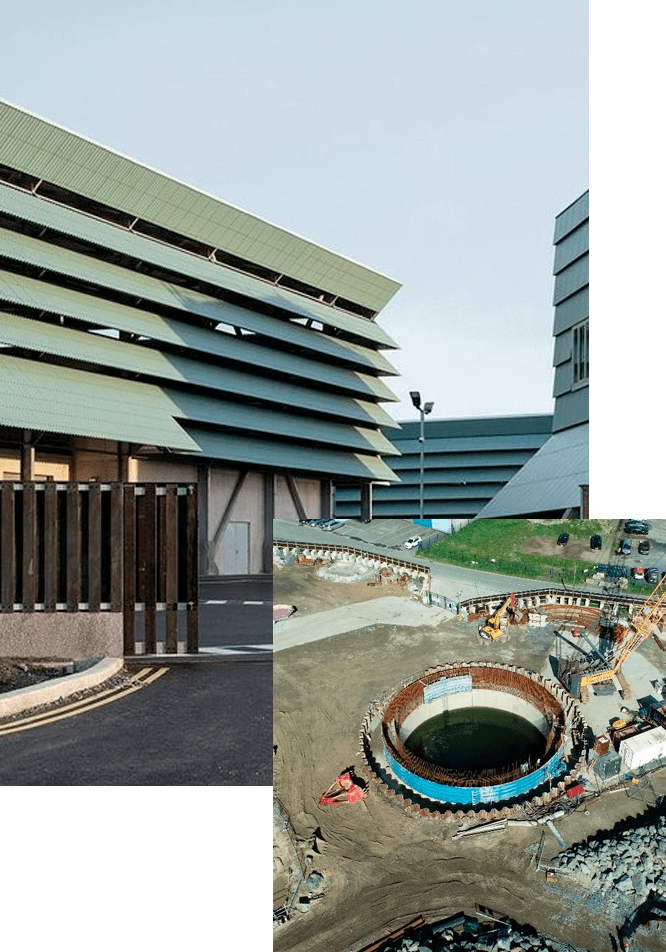

- Completion of the underground tunnel pipeline & shafts along the North Quay for the new interceptor sewer.

- Progress on the river-crossing tunnel and installation of the South Quay interceptor sewer.

- Installation of the 1000m offshore outfall pipeline, which was transported in three 310m sections from Norway and submerged in the summer of 2022.

Construction also included:

- A pumping station with a design capacity of 304 liters/sec, with capacity to serve up to 36,000 PE.

- Tunnelled pipeline under the Avoca River.

- New sewer connections to support future development.

Added value

Water Infrastructure with a Civic Identity and Design by Collaboration

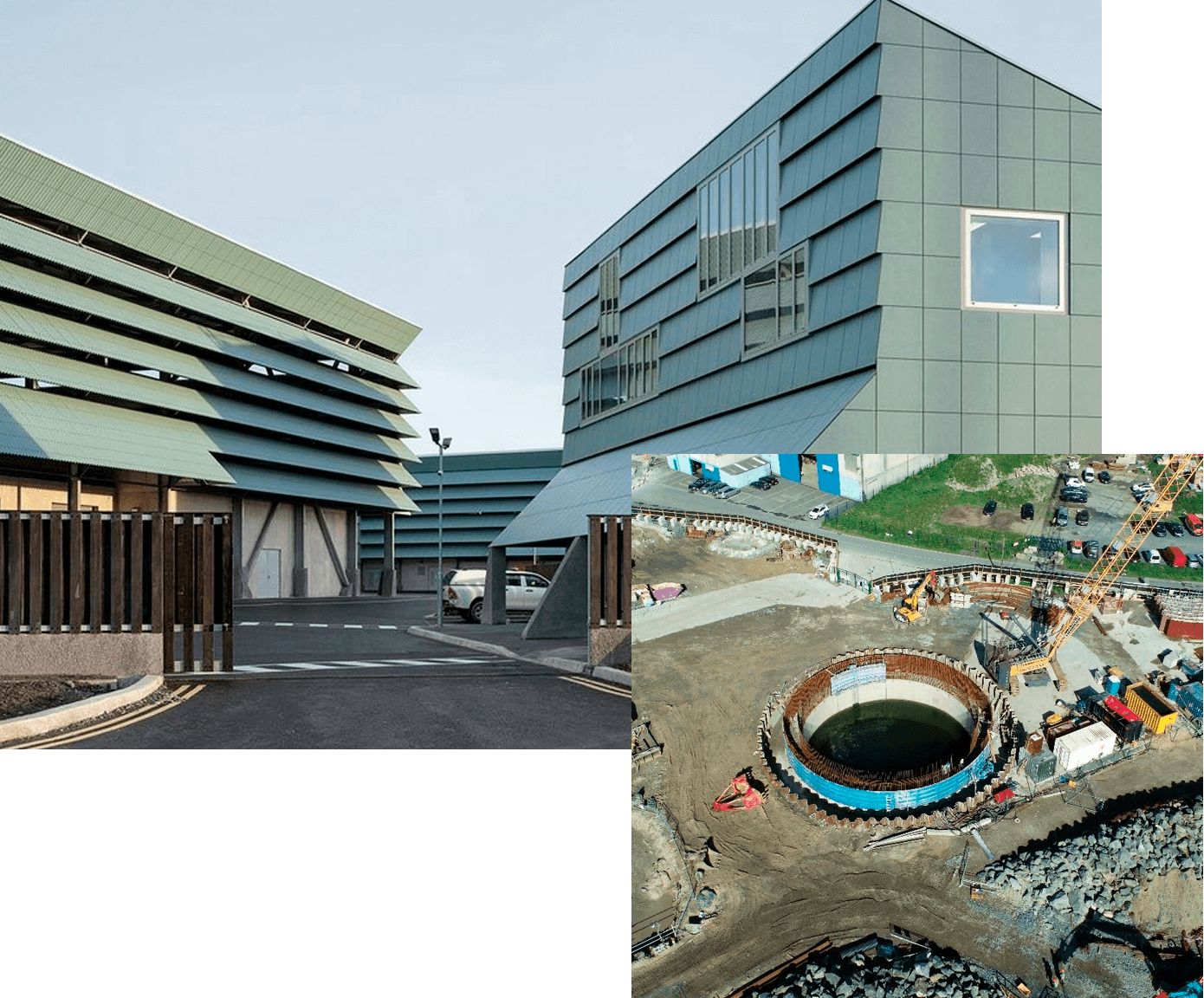

Built on a former industrial site, this wastewater facility reimagines public architecture. The project was true collaboration between the people of Arklow, architects and engineering design teams. In early consultations and design workshops, local knowledge, history, and aspirations were gathered and shared. These community conversations shaped the design approach, resulting in a facility that responds not only to environmental needs but to cultural and civic values as well. Architects Clancy Moore Architects won Irish Water’s public competition with a design that integrates the plant into the town’s maritime and industrial past. The result is a low-energy, above-ground system that minimises site disturbance and integrates sustainable features such as rooftop solar panels, and gravity-assisted flow.

Two low-slung, teal-clad buildings reflect the colours of local boats and flora, with louvred façades that support ventilation, odour control, and even offer habitats for bats and birds. The building’s louvred façades are engineered to promote natural ventilation and soften the visual impact over time. This layered cladding system, along with modulated structural proportions, ensures the building is visually engaging up close and from a distance. The result is a compact, low-energy approach to wastewater infrastructure. All treatment processes are placed above ground, avoiding the disturbance of pollutants left by the site’s former industrial use, with no need to remove soil. The processes are vertically stacked to minimise site coverage, and unlike a conventional plant that requires multiple energy-intensive pumps, this system relies on a single pump with gravity assisting the remaining flow — significantly reducing energy demand. To service the stacked forms, a gantry crane runs along the roof, which also hosts a PV solar farm to offset energy use. The main treatment functions are housed in two primary volumes, each clad in a louvred skin that distributes air, controls odour, and screens operations from view.

Materials and Sustainability

The design prioritises durable, low-maintenance materials that are both environmentally responsive and sensitive to the cultural context. The primary structure consists of reinforced concrete, forming the base and tank walls, while steel portal frames rise to support the superstructure. Main process buildings are clad in fibre cement panels—a non-toxic, fully recyclable material with a long service life and a reduced whole-life carbon impact. Sustainability is embedded throughout: a compact and efficient layout limits the footprint, avoids disturbing contaminated ground, and uses gravity-assisted flows to reduce energy demand. Rooftop solar PV panels further offset operational energy. Together, these strategies deliver a resilient, low-energy, and low-maintenance future.

Stakeholder Engagement & Community Impact

Minimising disruption to the local community was a key priority throughout the Arklow Wastewater Treatment Plant project. Several strategies were implemented to ensure smooth integration within the town:

- Traffic Management: Diversion routes, coordinated deliveries, and road upgrades were designed to minimize disruption for residents and commuters.

- Noise and Vibration Management: A detailed Noise and Vibration Management Plan (NVMP) formed part of the Construction Environmental Management Plan (CEMP) for the development, including real-time monitoring of noise, vibration, and air quality. Measures such as using quieter equipment, noise barriers, and limiting working hours helped protect the environment and local residents.

- Community Liaison: a 24/7 Community Liaison Officer engaged with locals, providing updates and addressing concerns throughout the project. A centralised online platform facilitated data sharing and ensured stakeholders stayed informed.

This approach successfully mitigated environmental impacts kept a positive relationship between the project and local residents.

Project Benefits & Innovations

This wastewater treatment plant delivers multiple benefits for Arklow, including:

- Environmental Protection: Eliminates raw sewage discharge, significantly improving water quality in the Avoca River and the Irish Sea.

- Flood Resilience: Includes emergency overflow structures at the plant and South Quay to manage extreme weather events and prevent local flooding.

- Urban Integration: Thoughtful architectural design ensures the plant is visually and structurally sympathethic with the town.

- Economic Growth: Provides essential infrastructure to support residential and commercial expansion in Arklow and the wider region.

Project milestones

Decades in the making:

- 1988: A wastewater treatment plant is first proposed for Arklow.

- 1993: The proposed site shifts to Seabank, sparking local controversy. Coastal erosion later makes this location unfeasible.

- 1994: Planning permission is granted for the first time. However, delays and disputes continue for decades.

- 2005: A new Environmental Impact Assessment Report (EIAR) is submitted. Planning permission is granted again.

- 2015: Planning permission expires.

- 2016: Uisce Éireann (then Irish Water) takes over responsibility for the project.

- 2018: Uisce Éireann conducts surveys along the North and South Quays, Arklow Bay, and the Avoca River estuary to inform design and the new planning application.

- 2018: Ayesa Engineering (previously ByrneLooby) undertakes surveys, reporting, and hydrological modelling as part of the Arklow Main Drainage Scheme.

- November 2019: Planning permission is granted by An Bord Pleanála.

- 2021: Project goes to tender.

- 2021: Construction begins at the North Dock site.

- November 2024: Plant construction is completed.

- January 2025: Plant is commissioned.

- April 2025: Official opening by An Taoiseach (Irish Prime Minister).

Awards won to date:

Architectural Association of Ireland:

Downes Medal recipient (never awarded to public infrastructure before)

Royal Institute of Architects Ireland (RIAI):

Winner - Public Buildings, Winner - Sustainability, Second Place - Public Choice

Shortlisted:

NCE, British Construction Industry Awards - International Project of the Year